Part 5 Circular Design - Adaptability & Life Cycle

2024.08.21

Welcome back to our blog series on circular design. Last time, we discussed how prioritizing cultural and climate resiliency and material durability in construction promotes the circular economy by extending a structure’s longevity. This episode corners the flip side of the longevity coin, asking how one might adapt a structure over time as culture and climate changes around it, and how designers might remain adaptable and agile as they confront the climate crisis through circular design.

Our project, the Star Garment Innovation Center, exemplifies this principle through its transformation of an outdated manufacturing building into a cutting-edge, eco-friendly facility. This project showcases how thoughtful retrofitting can create efficient, sustainable spaces while preserving the integrity of existing structures and furthering the circular economy.

Adapting to Local Conditions for a Climate-Sensitive Design

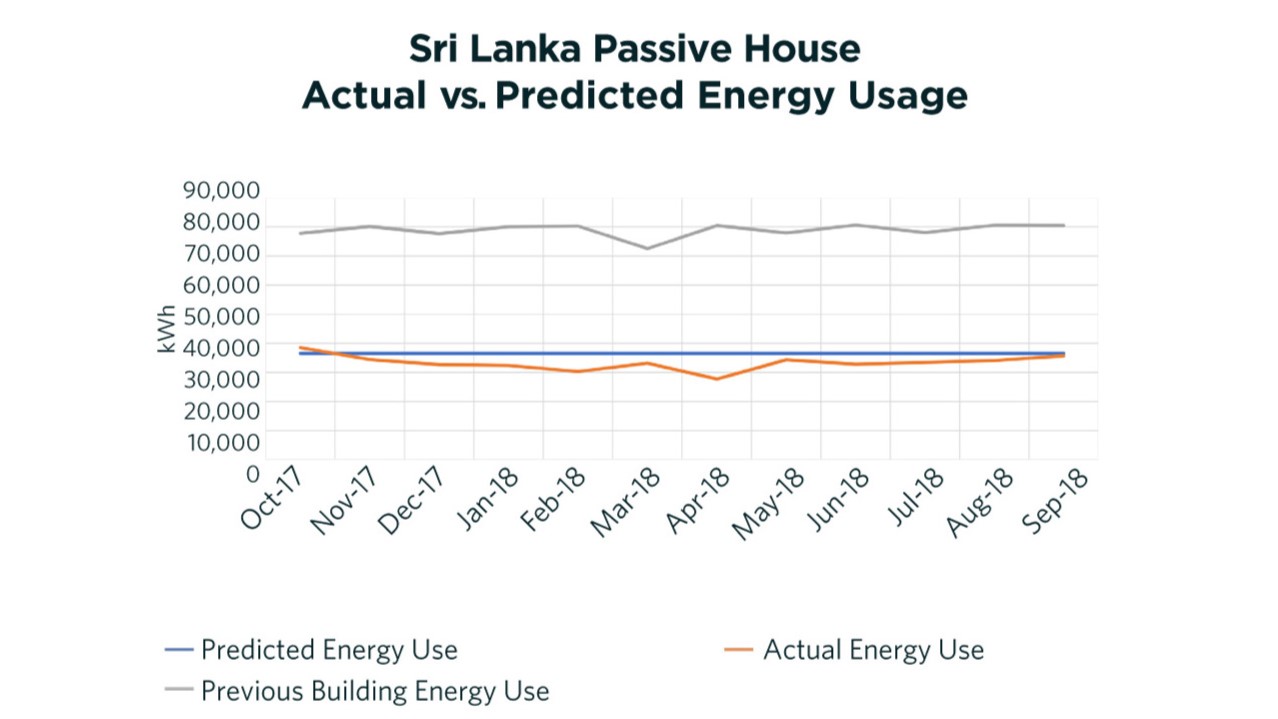

A standout feature of the Star Garment Innovation Center is its certification as the first Passive House project in South Asia, and one of only two globally for factory buildings. The vast majority of Passive House buildings are constructed in cool and temperate climates similar to Europe focused on keeping heat inside the building. Achieving Passive House EnerPHit certification in the tropical monsoon climate of Sri Lanka is characterized by high temperatures and humidity, which essentially reverses the typical energy challenges. Market forces also contributed to the challenge; few local builders had heard of the standard and essential materials and equipment were not available locally.

Circular combined Passive House principles and climate specific contextual solutions to demonstrate that high-performance, energy-efficient design is achievable even in the most demanding conditions. Shading to reduce equatorial solar heat gain was crucial: we pulled back the windows from the lower-level footprint to create a roof overhang for the first floors and designed playful industrial perforated metal to screen the upper floors from excess sun while permitting diffused light.

We worked closely with our local design partners and contractors to ensure proper training on Passive House techniques, including developing mock-ups for presentation to the builders. Circular’s design kept crucial details simple and used local, low-tech and contextually appropriate materials such as masonry as much as possible. To supply the absolutely necessary Passive House components, we had to research supply chains and delivery networks that would ensure the project wasn’t held up by delays- and remain flexible to new solutions if hiccups did occur along the way.

Circular combined Passive House principles and climate specific contextual solutions to demonstrate that high-performance design is achievable in the most demanding conditions.

Programmatic Flexibility

The Star Garment Innovation Center also excels in programmatic flexibility. In a rapidly changing industry like fashion, where trends and technologies shift constantly, this kind of adaptability is essential- A design approach based on maintaining large open floor spaces and minimal fixed machines allow production lines to be reformatted to create a new garment. The approach to the factory floor is extended to the rest of the project’s uses, including office spaces, showrooms, conference areas and worker canteen. This flexibility ensures that the facility can evolve with the company and occupant's changing needs, providing long-term value and reducing the risk of future obsolescence. By maintaining programmatic adaptability in the project’s layout, Circular was able to minimize the long term waste associated with altering the building for new purposes in the future.

Flexibility ensures that the facility can evolve with the company and occupant's changing needs.

Holistic Sustainability & Life Cycle Analysis

Underlying the Star Garment Innovation Center’s design is an embrace of holistic sustainability and a rigorous life cycle analysis that guided material selection and construction methods. We retained most of the existing steel structure, foundations and slabs in our design. New construction materials were sourced locally and were chosen for long term disassembly, re-usability and recyclability potential. These measures reduce embodied carbon associated with production of new materials, transport and demolition. Achieving Passive House Certification was of course another key goal in reducing the life cycle carbon emissions from the energy-intensive industrial program.

The retrofit wasn’t just about preserving the old; it was about transforming it into a model of modern efficiency. Our clients shared our commitment to transforming the environmental and human impact of the garment industry for the better. The facility now serves as a global benchmark for the garment industry, blending cutting-edge technology with worker-friendly environments.

The retrofit wasn’t just about preserving the old; it was about transforming it into a model of modern efficiency.