Part 7 How we did it: Star Garments Innovation Center - The Impact

2023.03.05

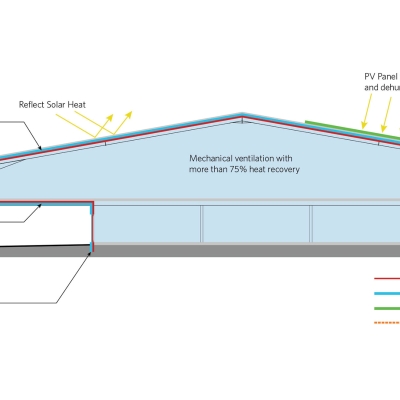

The project scope of work encompassed the gut renovation of an approximately 64,000 square foot existing two-story steel and concrete industrial building, to create a mixed-use office and production facility that was engineered to Passive House standards for efficiency and comfort.

By refurbishing the building to Passive House standards, the Star Garment Group was able to reduce the carbon footprint and improve performance tremendously when compared to building a brand-new conventional facility.

Thorough testing of the airtightness and remote monitoring of the ongoing energy usage provide quantitative confirmation of the building performance, achieving projected operational cost savings for the client and vastly upgraded workplace environmental standards for the employees.

Going the extra mile for Passive House certification was worth the effort because of its potential to serve as a model for future construction in the area, highlighting its benefits to budget, environment and worker conditions.

Individual systems saw significant increases in efficiency, in spite of the heavy demands created by the industrial equipment required for factory operation.

- Overall energy reduction exceeds 70% for the facility as compared to a conventional new building

- 90% reduction in dehumidification energy

- 73% reduction in heat pump energy

- 25x increase in insulation performance

A Collaborative Effort

This project would not have been possible without a firm commitment from the client as well as the passion and dedication from every member of the design, engineering and construction teams.

Energy consultants Steven Winter Associates (SWA) oversaw detailed analysis and testing to ensure components and assemblies met the strict criteria for certification.

Strict supervision by general contractor Tritech Engineering ensured that critical air barrier, window and wall assemblies from suppliers were installed correctly.

By promoting the project’s goals and inspiring the local building industry, Circular sought to establish a clear path to both reducing global carbon emissions and putting an end to worker “sweatshop” conditions.

By promoting the project’s goals and inspiring the local building industry, Circular sought to establish a clear path to both reducing global carbon emissions and putting an end to worker “sweatshop” conditions.

Honors & Awards

The project has been the recipient of numerous awards including AIA Brooklyn's Project of the Year and the PHIUS Passive House Projects Award.

Upon certification the Passive House Institute recognized the project's ground-breaking innovation with a Pioneer certification:

As Dragos Arnautu of PHI stated, "The Star Innovation Center in Sri Lanka shows that energy-efficient modernizations to the Passive House Standard are also possible in the tropical climate even with energy intensive building uses. After modernization, the building consumes substantially less energy and offers the workers a high level of comfort."

"We are delighted with the comfort and performance of our Passive House building and look forward to years of energy cost savings." - Charles Komar, CEO of Star Garment parent company Komar Brands

How we did it: Star Garments Innovation Center

Part 1

Passive House in Sri Lanka

2022.09.01

Part 1

Passive House in Sri Lanka

2022.09.01

Part 2

Efficient Adaptive Re-Use

2022.09.04

Part 2

Efficient Adaptive Re-Use

2022.09.04

Part 3

A Holistic Design Approach

2022.11.23

Part 3

A Holistic Design Approach

2022.11.23

Part 4

Strategies for Passive House Design in Sri Lanka

2023.03.01

Part 4

Strategies for Passive House Design in Sri Lanka

2023.03.01

Part 5

Getting it Built: Sri Lanka Edition

2023.03.02

Part 5

Getting it Built: Sri Lanka Edition

2023.03.02

Part 6

Performance Testing

2023.03.03

Part 6

Performance Testing

2023.03.03

Part 7

The Impact

2023.03.05

Part 7

The Impact

2023.03.05

Relevant Projects