Part 6 How we did it: Star Garments Innovation Center - Performance Testing

2023.03.03

An important aspect to building a Passive House project is performance evaluation, to ensure that the building meets the stringent standards for efficiency. While careful design and engineering can predict performance under optimal conditions, real-world testing is necessary to confirm that there are no issues with leaks or gaps in the air barrier.

Certification is only achievable for buildings that have been tested and can demonstrate they have achieved their design performance.

Blower Door Testing

At key points during the construction a blower door test is performed, which measures the airtightness of the structure and gives the builders a chance to fix any construction issues.

A testing unit is installed into the opening of a window or door with an airtight seal. A pressure difference (50 Pa) is created in the building with a speed-regulated fan and readings are taken to determine the air flow.

The procedure is used to detect leaks in the building envelope and to determine the air exchange rate. For a renovation project, the target for certification is to remain under 1.2 Air Changes per Hour (ACH), compared to 6 or more ACH for a comparable new conventional building. This is a measure of leakiness only - not an indication of the amount of fresh air that will ultimately be supplied by the ventilation system.

Certification is only achievable for buildings that have been tested and can demonstrate they have achieved their design performance.

Certification Challenges

A partial test of a portion of the window frame installation was done during construction to identify any unforeseen issues. The initial pressurization test revealed a few fabrication and installation conditions that prompted the team to optimize certain details.

At the final certification testing, the blower door revealed there was higher than acceptable air leakage, but the location of the issue was not immediately evident. Careful investigation using smoke puffers and anemometers eventually led the team to a concealed condition at the existing steel purlin to structural column connections under the roof.

Additional insulation and air-sealing was used to patch the gaps and eliminate the leakage at these locations. After applying the fix, re-testing confirmed that the final ACH rate was comfortably within the range for certification.

Up next: A look at the impact and benefits of this project.

Testing often reveals construction issues that can be corrected to achieve target performance.

How we did it: Star Garments Innovation Center

Part 1

Passive House in Sri Lanka

2022.09.01

Part 1

Passive House in Sri Lanka

2022.09.01

Part 2

Efficient Adaptive Re-Use

2022.09.04

Part 2

Efficient Adaptive Re-Use

2022.09.04

Part 3

A Holistic Design Approach

2022.11.23

Part 3

A Holistic Design Approach

2022.11.23

Part 4

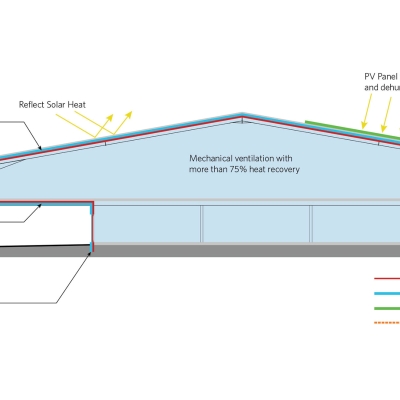

Strategies for Passive House Design in Sri Lanka

2023.03.01

Part 4

Strategies for Passive House Design in Sri Lanka

2023.03.01

Part 5

Getting it Built: Sri Lanka Edition

2023.03.02

Part 5

Getting it Built: Sri Lanka Edition

2023.03.02

Part 6

Performance Testing

2023.03.03

Part 6

Performance Testing

2023.03.03

Part 7

The Impact

2023.03.05

Part 7

The Impact

2023.03.05

Relevant Projects